Enhancing Productivity with Advanced Automation Solutions

Advanced automation solutions are transforming industries worldwide, offering businesses unprecedented opportunities to boost efficiency, streamline operations, and drive innovation. From manufacturing floors to complex supply chains, the integration of smart technologies is redefining how work is done, enabling enterprises to achieve higher levels of productivity and competitiveness in a dynamic global economy. Understanding the multifaceted applications and strategic benefits of these solutions is crucial for any organization aiming for sustained growth and operational excellence.

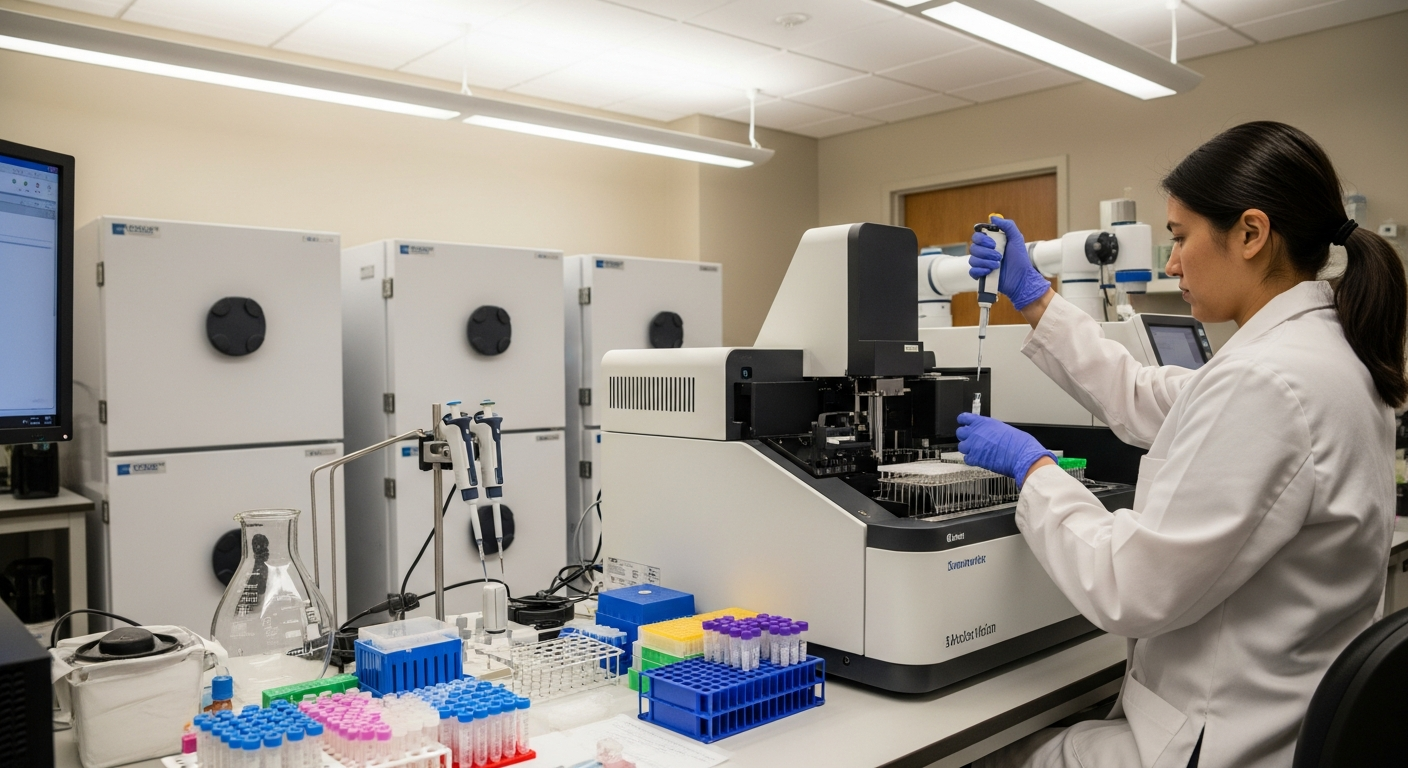

What is the Role of Automation in Modern Manufacturing and Production?

Automation plays a pivotal role in modern manufacturing and production by performing repetitive, dangerous, or precise tasks with consistent accuracy and speed. In manufacturing, automated systems, including robotic arms and CNC machines, handle everything from assembly and welding to quality control and packaging. This integration significantly reduces human error, increases output capacity, and optimizes resource utilization. The drive for higher production yields and improved product quality across various industries, including automotive, electronics, and consumer goods, is largely fueled by advancements in automation technology. These systems allow for continuous operation, leading to substantial gains in overall production efficiency and the ability to meet market demands more rapidly.

How Does Automation Impact Logistics and Supply Chain Operations?

In logistics and supply chain operations, automation is a game-changer for enhancing efficiency and responsiveness. Automated guided vehicles (AGVs) and autonomous mobile robots (AMRs) are increasingly common in warehouses for moving goods, optimizing storage, and fulfilling orders. Robotic process automation (RPA) streamlines administrative tasks like data entry, invoice processing, and inventory management, reducing bottlenecks and improving data accuracy. The adoption of advanced automation solutions in the supply chain helps organizations manage complex global trade networks, improve inventory visibility, and accelerate delivery times, ultimately leading to greater operational resilience and customer satisfaction. This digital transformation strengthens the entire supplychain infrastructure.

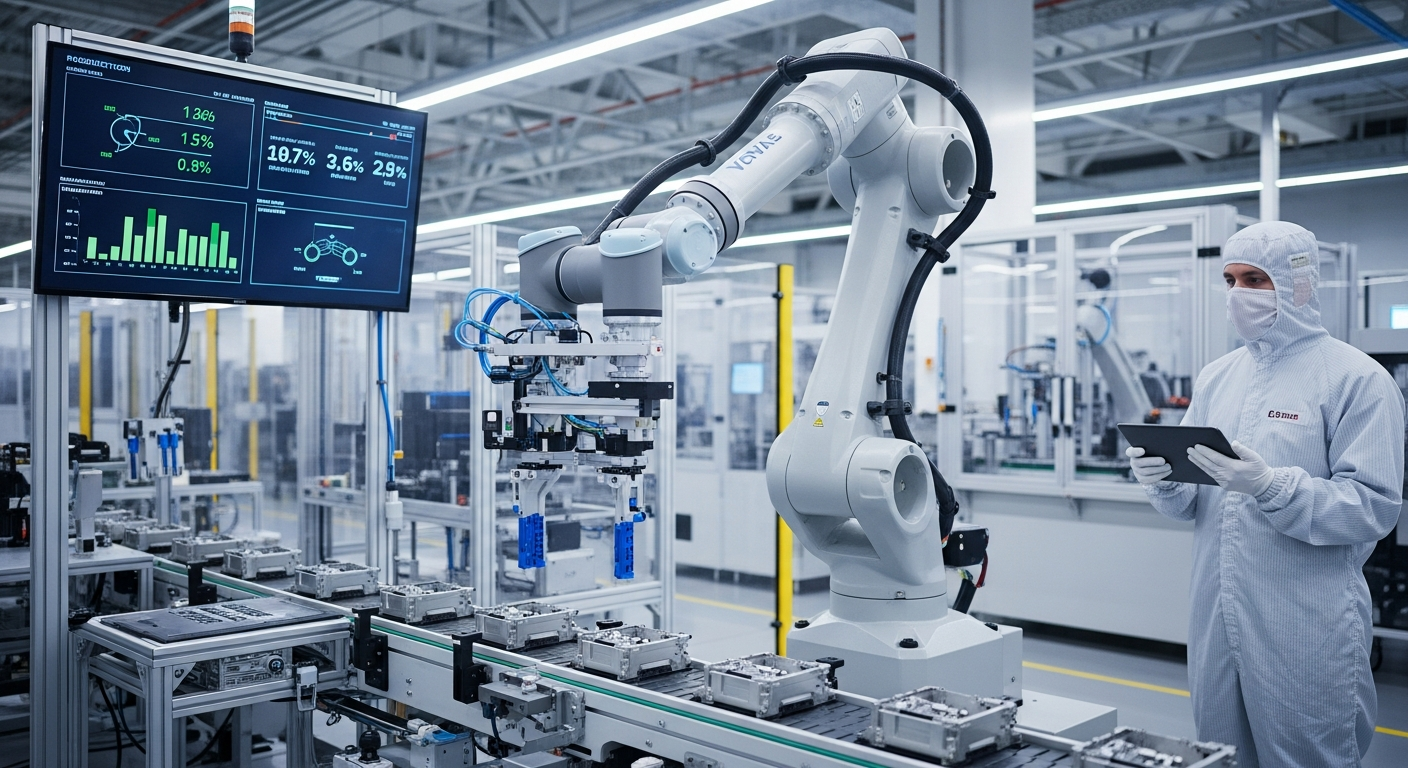

Exploring the Strategic Benefits of Automation for Enterprise Growth and Development

For enterprise growth and development, automation offers profound strategic advantages. Beyond immediate efficiency gains, it enables companies to innovate faster, adapt to market shifts, and scale operations more effectively. By automating routine tasks, businesses can reallocate their workforce to more strategic, creative, and value-added activities, fostering a culture of innovation. This strategic shift allows enterprises to develop new products and services, enter new markets, and maintain a competitive edge. Automation also provides valuable data analytics through integrated systems, offering insights into operational performance and customer behavior, which can inform future business strategies and drive sustainable growth.

What are the Considerations for Workforce Integration and Digitalization in Automation?

Integrating automation into the workforce requires careful planning and a focus on digitalization. While concerns about job displacement often arise, the reality is that automation frequently transforms job roles rather than eliminating them entirely. Companies must invest in reskilling and upskilling their employees to work alongside automated systems, focusing on areas like programming, maintenance, and data analysis. Digitalization efforts, such as implementing enterprise resource planning (ERP) systems and industrial internet of things (IIoT) platforms, are crucial for connecting automated processes and providing a holistic view of operations. This approach ensures that the human workforce and technology can collaborate effectively, leading to a more adaptable and productive enterprise.

Leveraging Analytics and Infrastructure for Enhanced Automation Efficiency

To truly maximize automation efficiency, robust analytics and a resilient infrastructure are indispensable. Advanced analytics, powered by artificial intelligence and machine learning, can process vast amounts of operational data generated by automated systems. This data provides actionable insights for predictive maintenance, process optimization, and demand forecasting, allowing businesses to make informed decisions that further enhance productivity and reduce downtime. A strong digital infrastructure, including reliable network connectivity, cloud computing resources, and cybersecurity measures, is fundamental to support these interconnected automated systems. Investing in the right infrastructure ensures seamless data flow, secure operations, and the scalability needed for future automation initiatives, underpinning the entire digital transformation journey.